Historic

2020

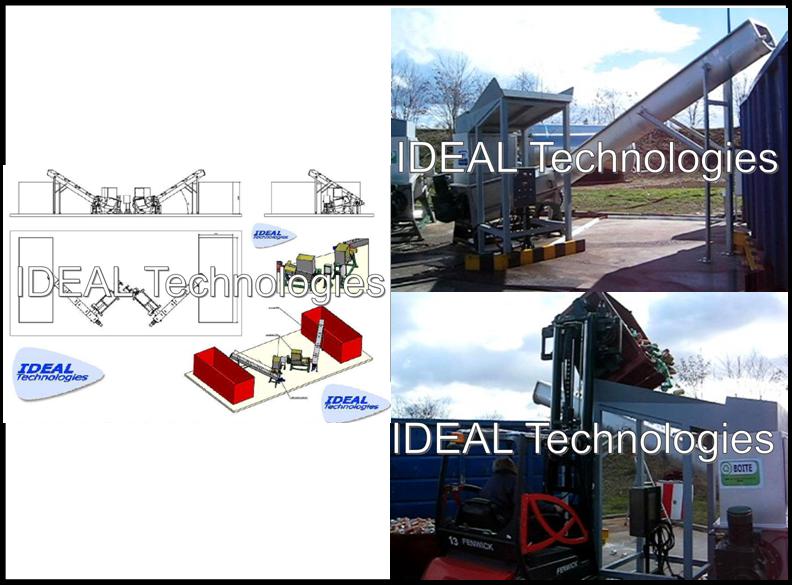

INSTALLATION OF DANONE MOROCCO DAIRY PRODUCTS SITES:

Spinning and Recovery Logistics Feedback

HDPE CAP SCREENING TEST

Danone Morocco

HDPE PLUGS

We always do more: here are screening tests to recycle HDPE caps on site.

We sort and press the caps for transport and recovery with our revolution ™ machines and IDEAL is happy to present the successful results of our tests, together with our partners.

Don’t hesitate to contact us for industrial waste management !

Sorting of HDPE caps, successful with our machines.

REVOLUTION 200 for liquid phase extraction and preparation at CSR

A Paddle Depacker biodeconditioner installed near Perpignan.

A BioDECONDITIONER tm

Paddle Depacker 25 M3/ hour, for unsold goods from supermarkets, scraps from IAA, SWOT

BIOMEL

The new patented system from IDEAL Technologies.

NEW SUCCESSFUL IMPLANTATION:

Drainage of sewage treatment plant pond sludge

LAUNCH OF OUR NEW ACTIVITY:

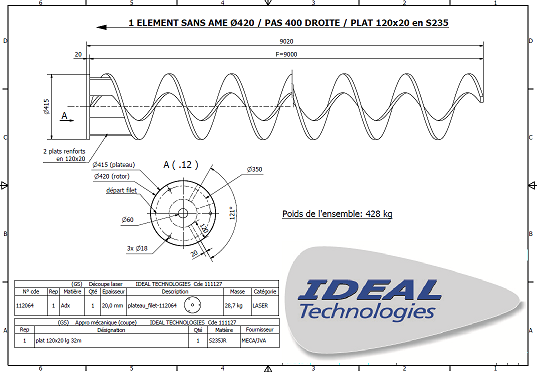

IDEAL conveying and draining screw

Supply from France: quality at the right price!

Meet on Wednesday December 3, at 9:30 am, at the BIOGAZ village

During the POLLUTEC Show, Eric DURIVAULT offers a conference "BioconditionneurTM", On the theme" Sorting and separation of packaged organic waste (GMS type) and Bulk shredding (RHF type) "

CILAM / YOPLAIT Emptying of dairy products Recycling of packaging and contents

Industrial installation of dewatering on pulper waste in the paper mill

Objective: production of CSR

CROIX-CHOLLOT

Implantation in an anaerobic digestion unit on the farm (300KW)

- Concentration of digestates

- Volume reduction for the use of fatal energies on site

- Guarantee of the use of thermal baths

Février 2012

4 L Trophy 2012

IDEAL Technologies becomes a sponsor of the largest humanitarian and student sports raid in Europe.

the 4 L Trophy, a double challenge:

- A Sports Challenge: 6000 km (including 700 km of desert tracks in the great south of Morocco).

- A Humanitarian Challenge: send more than 50 tonnes of donated school supplies to child protection centers.

The 1563 crew, made up of Benoît Labouise and Edouard Deleau, two young people from Poigny la Forêt, carry the colors and values of IDEAL Technologies high.

http:/www.facebook.com/page/participation-au-4L-trophy-2012quipage-1563-/226350400728483

Février 2009

New IDEAL Technologies installation at Refresco

New IDEAL Technologies installation at Refresco (Pepsi Cola bottler), in Saint Alban-les-eaux (France).

Deux revolution 200 en parallèle avec chacune sa vis d’alimentation :

- Spinning of PET and metal cans waste.

- Recycling of packaging and recovery of content.

"Entrepreneurs: The great stories of Innovation in Ile de France"

January 29, 2010 at 7:30 p.m.

"Entrepreneurs", In the presence of Mr. Jean-Paul HUCHON, Chairman of the Ile de France regional council.

At the Paris 12th arrondissement Center for Innovation

Met during the opening of the photo exhibition, Jean Paul HUCHON congratulated Eric DURIVAULT for his contribution in terms of innovation. He welcomed the proposals for the treatment of "Green algae" on the Breton coast submitted to the interministerial mission by IDEAL Technologies.

Spotlight on the occasion of the INNOV’ECO trade fair

December 2009, interview with Eric DURIVAULT

Click on the image to view the video on the INNOV’ECO website

IDEAL TECHNOLOGIES at POLLUTEC

This year, we presented our new I.Tech dryer using fatal energies on an industrial site; as well as our digestate drying facilities from methanization units with thermals from biogas engines

Avril 2010

IDEAL TECHNOLOGIES goes international

Welcome to Me Maud Taillard who will represent IDEAL Technologies in Mexico and Latin America.

REVOLUTION 150 all stainless steel

Dairy product deconditioning facility

Flow: 1m3/hour

SMED

Meet the next edition of SMED which will take place from 2 to 4 June 2010 at the Paris Stock Exchange.

REVOLUTION 500 on platform

Air conditioning platform REVOLUTION 500 with a carpet

Novembre 2009

Delivery of a REVOLUTION 400 tm second hand

This equipment, installed near Angers (49) on the sorting package of organic packaging and waste, has a treatment capacity of 4m3/hour.

Loss of waste -10%

HERO was awarded by ADEME thanks to the technology REVOLUTION

Reduce the volume of waste and find valuation lines.

The company displays the triple profit of its actions:

- The economic benefit: increase of revenue thanks to recycling. Costs divided by 5.

- The ecological benefit: reduction of the impact on the environment thanks to the appreciation of waste.

- Human benefit: The waste management plan reinforces the mobilization and internal image of the company. Strong implication of all, from employees to management. Trophy «Internal communication».

Danone to Volvic

Drying of PET bottles in wreckage - from 33 cl to

Delivery of a REVOLUTION 2500 for the company Echalier

To be mobile, the REVOLUTION 2500 is mounted on the empire.

IDEAL TECHNOLOGIES IN THE OCEAN INDIA

Start-up of the activity of our agent Patrick VERNY of the company AC2V in the INDIAN OCEAN Zone. AC2V works daily to improve the impact of its customers' activities on the environment.

Janvier 2008

FEATHER SPIN

CRETE D'OR - REUNION ISLAND

IDEAL Technologies delivered a REVOLUTION 400 stainless steel to

This equipment is intended for wringing feathers to reduce density and weight.

Objective: extract 50% of liquids

Mai 2007

SENOBLE equips itself with a REVOLUTION 400 Inox to process its yoghurt production waste

- Automatic feeding of the REVOLUTION TM machine by means of a grasshopper.

- Flow: 4 m3/ hour

- Spinning up to 90% of production waste

2006 ENVIRONMENTAL AWARD for the Coca-Cola Enterprise factory in Milton Keynes (GB)

The REVOLUTION TM solution for full packaging: PET and aluminum cans

The British Milton Keynes plant received the 2006 "letsrecycle.com" environmental award thanks to the REVOLUTION processTM. This award recognizes the company that divided the volume of waste going to landfill by 10. Thanks to the REVOLUTION processTM, the plant sends less than 2% of its waste to landfill. A success for the Milton Keynes plant, which meets the group’s environmental concerns.

Building on this winning partnership, the Coca-Cola Enterprise plant in Alicante (Spain) has just acquired a REVOLUTION machineTM 400.

Objective: 90% reduction in the volume of full production rejects.

PRESENTATION OF THE NEW REVOLUTION 150R

Keen interest from industry and environmental service companies.

More than 200 contacts established including around 50 qualified industrial projects.

The marketing effort initiated before the show on the specific needs of slaughterhouses and paper mills proved successful and enabled projects to be initiated in these two segments.

The entire team of the IDEAL group thanks you for your trust. This is what she commits her energy to.

Juin 2006

MATERNE RECYCLES ITS COMPOTES

Installation of a set including a machine REVOLUTION 400 stainless steel with a bin tipper at the Boué plant (02) for the treatment of compote production waste and the compaction of DIB.

Development : tests are underway to experiment with the mechanical drying of organic materials by "Fluidiser". With 5 kW of power, we can hope to extract 46% of water from the apple grains.

RECYCLING OF PLASTICS

Installation of an integrated assembly in a production line for the dewatering of plastic recycling production waste for FREUDENBERG-POLITEX.

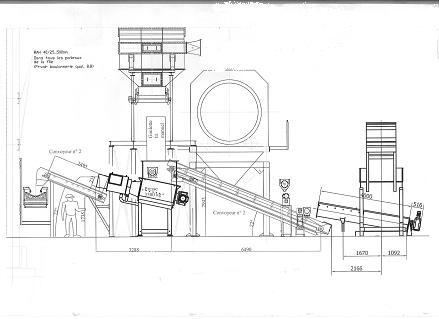

This installation includes: a rocker, an extractor screw, a REVOLUTION 2000 spinning machine, a phase separator (sorting of liquid materials).

This equipment extracts over 40% moisture, resulting in weight savings and an overall reduction in the cost of waste treatment.

Septembre 2006

RENTAL CHICKEN FEATHER SPIN (72)

50% less water at the outlet

The validation of the composting process is in progress.

Juin 2006

EMPTYING ICE CREAM BINS

Installation of a REVOLUTION 400 machine TM Stainless steel for Häagen Dazs in Arras, incorporating an ice cream heating system.

- Emptying of individual ice cream pots and collective catering ice cream tubs.

- Weight and volume savings on treated DIBs.

- Validation in progress for the use of organic materials in the animal feed sector.

EMPTYING BULK SOUP BRICKS

Campbell France carried out an on-site test of emptying bricks of soup for its Liebig plant in Pontet near Avignon (84).

Octobre 2005

HERO RECYCLES ITS COMPOTES

Installation of a machine REVOLUTION 2000 at the Allex plant (26) for the treatment of applesauce production waste and the compaction of DIB.

Novembre 2005

A PILOT SITE CONDUCTED BY IDEAL BENNECO

A test operation implemented throughout the 2005 harvest on the CRAMANT pilot site (51) shows in real life the value and efficiency ofclean delivery and storage systems as well as the treatment of marc. from pressing centers.

For clean harvestingthe REVOLUTION® dewatering system® from IDEAL Technologies combined with the Benneco® double-bottom bucket system® is an essential step in an environmentally friendly wine industry..

EXHIBITION IN LUXEMBOURG

at our partner GROSSBUSCH in ELLANGE

Présentation de

IDEAL Technologies in "Behind the Scenes of the Economy"

Program presented by Jean Marc Sylvestre

broadcast on TF1, Thursday February 19, 2004

November 2004

Pollutec 2004 trade fair:

65,000 visitors,

IDEAL Technologies will have achieved:

The 40th REVOLUTION machineR sold !

Thank you for making this fair a success.

GMS EQUIPMENT FAIR

LAUNCH OF THE NEW REVOLUTION MACHINE 150

Success confirmed in front of the keen interest of supermarkets who see in this machine a space-saving solution to reduce their waste flow by 50%..

Dairy demonstration

Emptying of Tetrapak and HDPE bottles from 1L to 33 cl.

Prototype dump with CRITT

Study of a dump prototype for frozen and frozen products in collaboration with CRITT Ile de France.

CRITT seals its collaboration with IDEAL Technologies

Successful partnership for the creation of an industrial prototype for emptying and trivializing the packaging of solid cosmetic products (creams).

ORGANIC PRODUCTS SPIN TEST

Ordering a wringing test of organic products for composting.

This test was done in collaboration with

We have validated the ability to extract more than 25% of liquids from the organic fraction..

Our Canadian client therefore intends to master and control the composting of curbside and organic collection on site.

Immediate savings:

Lower rotations: mobile machine

Recycling possible: no more landfill

Volume reduction: 1 outgoing for 45 incoming!

INDUSTRIAL TEST OF FEATHER SPINNING

The on-site demonstration of the extraction of water from drip-fed feathers validated an extraction rate of over 50%.

The destructuring of the feather makes it possible to consider its use in the composting sector.